No products in the cart.

Double Durston

£3,048.00 exc. VAT

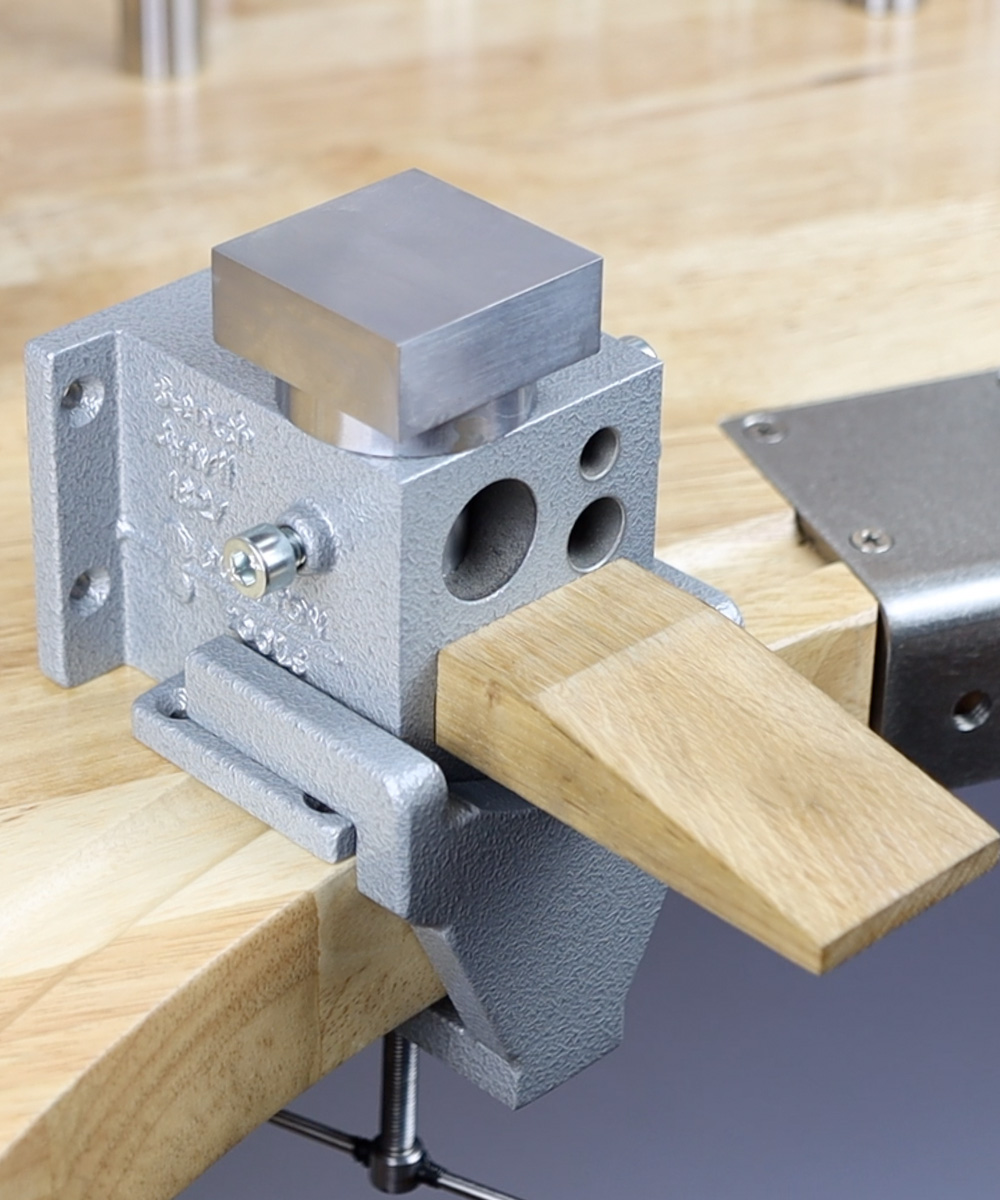

Double Rolling Mill – Double Durston rolling mill from Durston Tools.

Comprises of 2 of our DRM Rolling Mills, the DRM F130R and the DRM W130E combined with a very sturdy Double Rolling Mill Stand.

In stock

SKU: 1053 Categories: Manual Rolling Mills, Double Rolling Mills, Double Rolling Mills Tags: Combination, Gearbox

Double Rolling Mill – Double Durston rolling mill from Durston Tools.

Comprises of 2 of our DRM Rolling Mills, the DRM F130R and the DRM W130E combined with a very sturdy Double Rolling Mill Stand.

| Weight | 126.7 kg |

|---|

Rolling Mill Questions & Answers

My Durston Rolling Mill does not have side extensions, Can I add them?

Unfortunately it is not possible to add side extensions to a Rolling Mill. Please consider this if you are looking to purchase a new rolling mill and what your current and future requirements may be.

- If your rolling mill does not have extension rollers. So the "R" models or the Agiles for example then extension rollers cannot be added.

- If there are no shafts protuding from the left hand side of your mill then extension rollers cannot be added.

- It is not feasible to purchase new rolls to swap out on your rolling mill as the cost is the same as a new rolling mill.

- Please note that the sizes of the grooves on the extension rollers will normally be within a tolerance of plus or minus .3mm

Can I use two half round extension rollers to make round wire?

It is possible to use two half round extensions if your rolling mills supports extension rollers but you will need to re-order the 2 extension rolls together and inform us that they are to match, this way we can machine them as a matching pair.

Please note: You will not get perfect round with this solution. It will be oval shaped.

What is the difference between a rolling mill with reduction and one without reduction?

A rolling mill with no reduction (direct drive) means that when you turn the handle round once the rolls go round once.

A Rolling mill with reduction (with gearbox), let's say 4-1 means you will have to turn the handle four times for the rolls to go round once. A reduction of 5-1 means you must turn the handle five times for the rolls to go round once. Having a reduction gearbox makes lighter work of rolling.

What is Direct Drive?

Direct Drive means there is no gearbox on the rolling mill, the handle is linked directly to the rollers with no reduction.

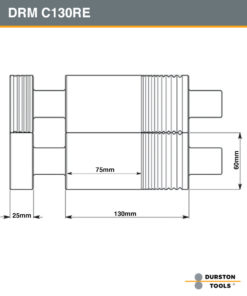

If the model number has an "R" then it has a Reduction Box

If the mode number has an "E" It means there are side extensions

If the model number has "RE" then it has a reduction gearbox and side extensions

Can I add a reduction gearbox to a mill that was not supplied with one?

Unfortunately, reduction gearboxes cannot be added retrospectively.

Can I turn my manual mill into a powered mill?

Unfortunately, it is not possible to change a manual rolling mill to a powered rolling mill.

Which oil should I use to protect my rolls from rust? and what grease do I need to use on the gears?

For the Rolls, the best oil to use is ‘3-in-1’’ oil to protect your rolls, apply layer with a cloth after use or regularly if not in use for long periods of time.

For the gears, we use lithium soap thickened grease when we are making the mills, but any standard gear grease can be used.

There are black marks on my rollers, what can I do?

Sometimes the rollers do develop marks, but it will not affect the use of your mill at all and it will still work perfectly.

What are the differences between the Agile and DRM Rolling Mills?

The Agile mills have a T bar instead of a handwheel and do not have extension rollers. The Agile mills also have additional half rounds on the main roll so it has less flat area.

DRM Rolling Mills have the round adjustment wheel, optional side extensions (E Models) and different roll / groove options.

Other than these differences, the mills are the same and offer the same performance.

I have an older generation Durston Rolling Mill, can I buy extension rollers or other spares?

Yes we do keep some spares for older generation Durston Rolling Mills

Older generation models have extension rollers which are 19mm wide. All of the extension rollers sold today are 25mm wide. These will still work with your older rolling mill but you will not be able to fit the circlip (black ring) on.

This will not affect the performance.

If in any doubt, please email us a picture of your rolling mill and we will advise.

What is the minimum and maximum thickness of material that can be rolled?

Generally, the minimum – maximum thickness is 0.1mm – 6mm

How thin can your mills roll material?

As a rough guide divide the diameter of the roll by 750.

For example, on Agile 110 the diameter is 50mm so 50 divided by 750 is 0.66mm

In fact, you can divide it by between 500 to 1000.

It depends on the width of material and the hardness but dividing by 500 to 1000 gives a good idea.

So basically, you can roll down to between 0.50 and 0.1mm depending on hardness.

If it is 30mm wide, then it might go to 0.1mm

If material is 10mm wide and soft it will roll down to .05mm

How long is the turning lever?

The turning lever is 35cm from the centre of the hole where it attaches to the mill to the end of the handle.

How do I use the dial on top of my rolling mill?

The dial is just a guide and does not provide exact measurements.

How do I avoid “fins” on my rolled material?

The best way to minimise is, do not roll with rolls closed. Have them open approximately 0.3mm and turn the wire 90 degrees on each pass.

How can I clean the steel rolls? Is there a specific product I need to use?

When the rolling mill is not in use, apply a thin coating of rust preventative liquid. Using a clean and dry paint brush (approximately 12mm wide) apply the rust preventative across the rolls. Turn the rolls as you do this. Make sure the rolls are nearly closed. This will spread the liquid evenly over the surface. It is very important that your rolls are always protected, especially in moist/wet/hot conditions or where temperatures are changing. Once your rolls are marked/rusty/corroded they will be like this until you have them removed and reground. (However, please note that it is almost impossible that you will end up with perfect rolls. Over time and use they will get slightly marked but will still work perfectly well). When using your mill again remove all rust preventative and ensure your rolls are clean and dry before you start to roll material.

It is also recommended that you cover your mill when not in use. This is to prevent the rust preventative from collecting dust and dirt.

Keep the rolls clean. Do not touch the rolls. Oils and acids from your body can damage the rolls, leaving behind small marks and eventually

rust.

Make sure all material is dry before rolling.

Ordering FAQs

Do you ship worldwide?

Yes we ship worldwide, please add items to the checkout and enter your address for a shipping cost.

Can I place my order over the phone?

You are welcome to call or email for help or information on any of our products but we are only able to accept orders and payments via our website, this allows us to give a better service and ensure all your details are correct.

How long does delivery take?

We aim to ship all orders within a few days of ordering, depending on where you are in the world it may take only a couple of days or up to a week to arrive. We use DPD for UK deliveries and DHL for worldwide shipments. Larger orders such as Benches or heavy Rolling Mills will be sent on a pallet.

Related products

£820.00 exc. VAT

SKU: 1003

£993.00 exc. VAT

SKU: 1029

£1,078.00 exc. VAT

SKU: 1026

£1,594.00 exc. VAT

SKU: 1044